- HOME

- SEPAREL Technology

- Applications

Applications

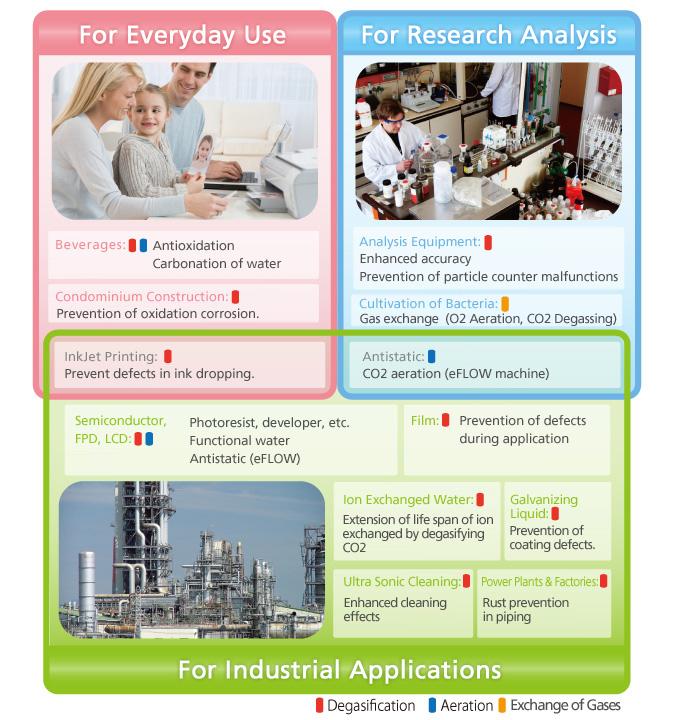

To learn about degasification and aeration, please visit "What is Degasification & Aeration?" On this page, you can learn how SEPAREL is used in everyday life.

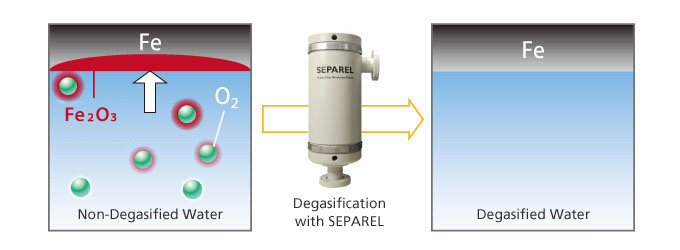

Degasification technology is used to protect piping in factories and power plants.

Because oxygen is dissolved in water, iron piping will become oxidized and rusted if untreated water is used. Piping rust can be prevented through degasification and the removal of oxygen from water. Membrane degasification does not require chemicals.

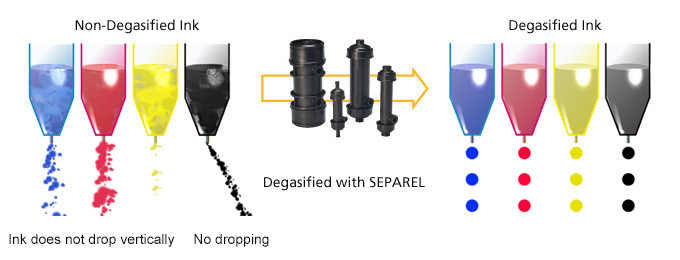

Degasification technology is utilized for high-quality ink jet printing.

Inkjet printing requires printing ink to be ejected from small nozzles. When air is dissolved in inkjet ink, the oxygen can form air bubbles which cause poor ejection. This problem can be solved through degasification of ink prior to jetting.

Degasification is essential in the biochemical field which protects our health.

Blood collected by blood tests is analyzed by biochemical analyzers. If blood samples and reagents contain bubbles, it will prevent precise analysis. To improve the analysys accuracy, degasification technology is essential.

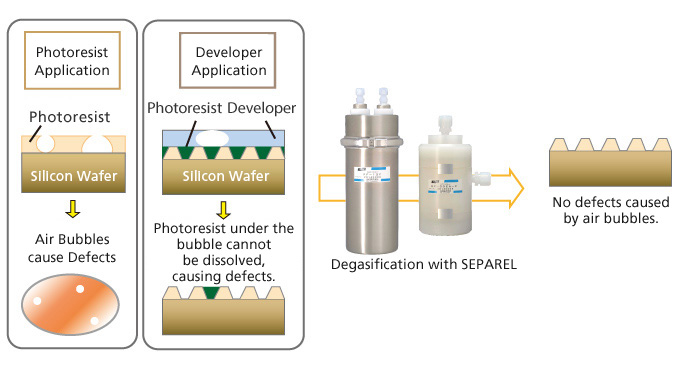

Degasification technology is utilized for the microfabrication of semiconductors, liquid crystal displays, and flat panel displays.

During microfabrication of electronic materials, tiny bubbles will cause defects. SEPAREL supports microfabrication processes by degassing various liquids, such as photoresist and developer.

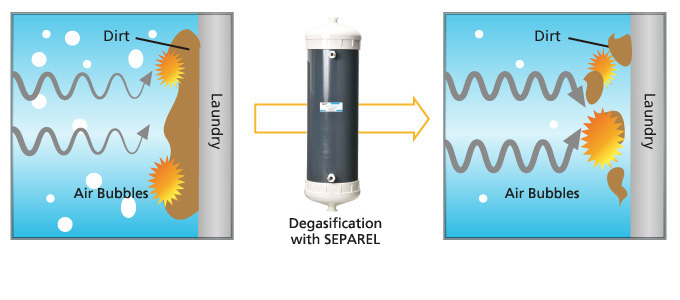

Degasification is useful for improved detergency.

In the case of ultrasonic cleaning, dissolved gases in water may reduce the effect of ultrasonic waves, causing poor cleaning. The removal of dissolved gases in water via degasification allows for more efficient cleaning.

SEPAREL is also utilized in various other industries.

With increased quality controls and more precise processing in recent years, degasification is becoming an integral part of numerous industries and applications. Also, new applications for degasification are being discovered and developed every day.

If you have a problem with dissolved gases or air bubbles in any liquid for any application that is not listed here, please contact DIC for clarification.

- Please visit our Features page for more information on DIC’s proprietary hollow fiber membrane technology for degasification and aeration.